Additive Binder Jets Market to Accelerate with Increasing Adoption in Industrial Additive Manufacturing

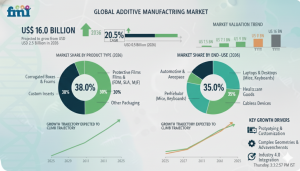

MD, UNITED STATES, February 11, 2026 /EINPresswire.com/ -- The global Additive Binder Jets Market is projected to expand from USD 2.5 billion in 2026 to USD 16.0 billion by 2036, registering a robust CAGR of 20.5% over the forecast period, according to Future Market Insights (FMI). This rapid growth reflects binder jetting’s transition from a prototyping-focused technology into a mainstream, production-grade manufacturing platform across aerospace, automotive, and industrial sectors.

Significant improvements in powder metallurgy, sintering efficiency, and AI-enabled process optimization during 2025 and 2026 have accelerated commercialization. The integration of artificial intelligence has reduced production cycle times by approximately 35%, while maintaining dimensional tolerances within ±0.1 mm, positioning binder jetting as a viable alternative to traditional casting and machining for complex, high-volume components.

Partnerships and Industrialization Drive Scale

Strategic collaborations between equipment manufacturers, material specialists, and end users are becoming the dominant model for scaling binder jetting. Jacob Brunsberg, Binder Jet product line leader at GE Additive, emphasized this shift, noting that partnerships with companies such as Sandvik are central to industrializing innovation and accelerating commercialization.

This ecosystem-based approach reduces qualification risk, improves material consistency, and shortens time-to-production—critical factors for aerospace and automotive manufacturers seeking repeatable, certified processes.

Government Funding and Regulatory Recognition Accelerate Adoption

Public sector support has reinforced binder jetting’s strategic importance. In October 2023, the U.S. Department of Energy allocated USD 14.9 million to advance binder jetting research through GE Research and voxeljet, signaling federal recognition of the technology’s role in strengthening domestic manufacturing resilience.

Regulatory acceptance has further expanded addressable markets. The Federal Aviation Administration’s approval of additively manufactured components for commercial aircraft in 2024 unlocked new aerospace opportunities, while evolving automotive standards now permit binder jet components for non-critical systems, broadening industrial adoption.

Material Expansion Unlocks New Applications

A major inflection point occurred between 2024 and 2026 with expanded material compatibility. Desktop Metal’s introduction of reactive metal processing for titanium and aluminum removed historical constraints that limited binder jetting primarily to stainless steel and bronze.

This development significantly expanded the technology’s relevance for aerospace, automotive lightweighting, and medical device applications, where titanium and aluminum alloys are essential.

Cost Democratization Broadens Market Access

Market expansion accelerated in 2025 with the launch of more affordable systems. Sinterjet’s USD 65,000 binder jetting platform represented a roughly 60% reduction in system cost versus enterprise-grade solutions. This price shift is enabling small and medium enterprises to adopt binder jetting for specialized applications, including jewelry, precision components, and short-run industrial production.

As affordability improves, binder jetting is evolving from a capital-intensive niche technology into a broader manufacturing tool accessible across multiple tiers of the industrial ecosystem.

Metal Binder Jetting Dominates Market Mix

By material type, metal binder jetting accounts for approximately 68.5% of market revenues, driven by aerospace and automotive demand for complex, high-strength components. Established metal powder supply chains and standardized post-processing workflows have lowered adoption barriers and improved scalability.

Sand and Foundry Applications Emerge as Growth Adjacent

Sand binder jetting represents a fast-growing adjacent segment, accounting for 13.3% of market share, particularly in foundry tooling and casting core production. This application enables rapid development of complex molds and cores, reducing casting lead times from weeks to days and eliminating multi-part assemblies.

Government-backed initiatives, including voxeljet’s collaboration with GE Research under U.S. Department of Energy funding, are advancing large-format sand printing for industrial-scale foundry applications.

Manufacturing Economics and Sustainability Support Adoption

Binder jetting delivers compelling economics for batch sizes between 100 and 10,000 units, where it often undercuts traditional machining and tooling-intensive casting. Powder recycling rates of approximately 95% significantly reduce material waste, particularly for high-cost metals such as titanium and tool steels.

From a sustainability perspective, reduced scrap rates, lower tooling requirements, and increasingly energy-efficient sintering processes align binder jetting with circular economy and low-waste manufacturing strategies.

Regional Growth Led by Asia Pacific

Asia Pacific is expected to register the fastest growth, led by China at 22.0% CAGR, followed by Germany at 20.0%, and the United States at 19.5%.

China (22.0% CAGR): Driven by government manufacturing modernization programs and large-scale investment in additive manufacturing under national industrial policy frameworks.

Germany (20.0% CAGR): Supported by Industry 4.0 initiatives, automotive transformation, and strong machine tool and materials ecosystems.

United States (19.5% CAGR): Anchored by aerospace, defense, and medical device applications, supported by federal research funding and regulatory acceptance.

Japan (18.5% CAGR): Focused on precision manufacturing, electronics, and automotive prototyping and low-volume production.

Key Players in the Global Market

GE Additive

Desktop Metal

HP Inc.

voxeljet

Markforged

Digital Metal

Sandvik

Kennametal

ArcelorMittal

Sinterjet

Addimetal

Request For Sample Report | Customize Report |purchase Full Report -https://www.futuremarketinsights.com/reports/sample/rep-gb-31944

Competitive Landscape Shifts Toward Integrated Solutions

Competition in the additive binder jets market is increasingly defined by vertical integration and ecosystem control, combining equipment, materials, software, and application expertise. Leading players are positioning themselves as end-to-end solution providers, rather than standalone machine vendors.

Software capabilities—particularly AI-driven process optimization, real-time monitoring, and predictive quality control—are becoming key differentiators, creating customer lock-in and improving production reliability.

Government-supported R&D partnerships, such as voxeljet’s collaboration with GE Research, further reinforce technology leadership and accelerate commercialization.

Explore More Related Studies Published by FMI Research:

Human Papilloma Virus Testing Market- https://www.futuremarketinsights.com/reports/human-papilloma-virus-testing-market

Cell Culture Waste Aspirator Market- https://www.futuremarketinsights.com/reports/cell-culture-waste-aspirator-market

Pharma Peeler Centrifuge Market- https://www.futuremarketinsights.com/reports/pharma-peeler-centrifuge-market

Pharmaceutical Continuous Manufacturing Equipment Market- https://www.futuremarketinsights.com/reports/pharmaceutical-continuous-manufacturing-equipment-market

Pharmaceutical Liquid Prefilters Market- https://www.futuremarketinsights.com/reports/pharmaceutical-liquid-prefilters-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why FMI: Decisions that Change Outcomes- https://www.futuremarketinsights.com/why-fmi

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware – 19713, USA

T: +1-347-918-3531

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.