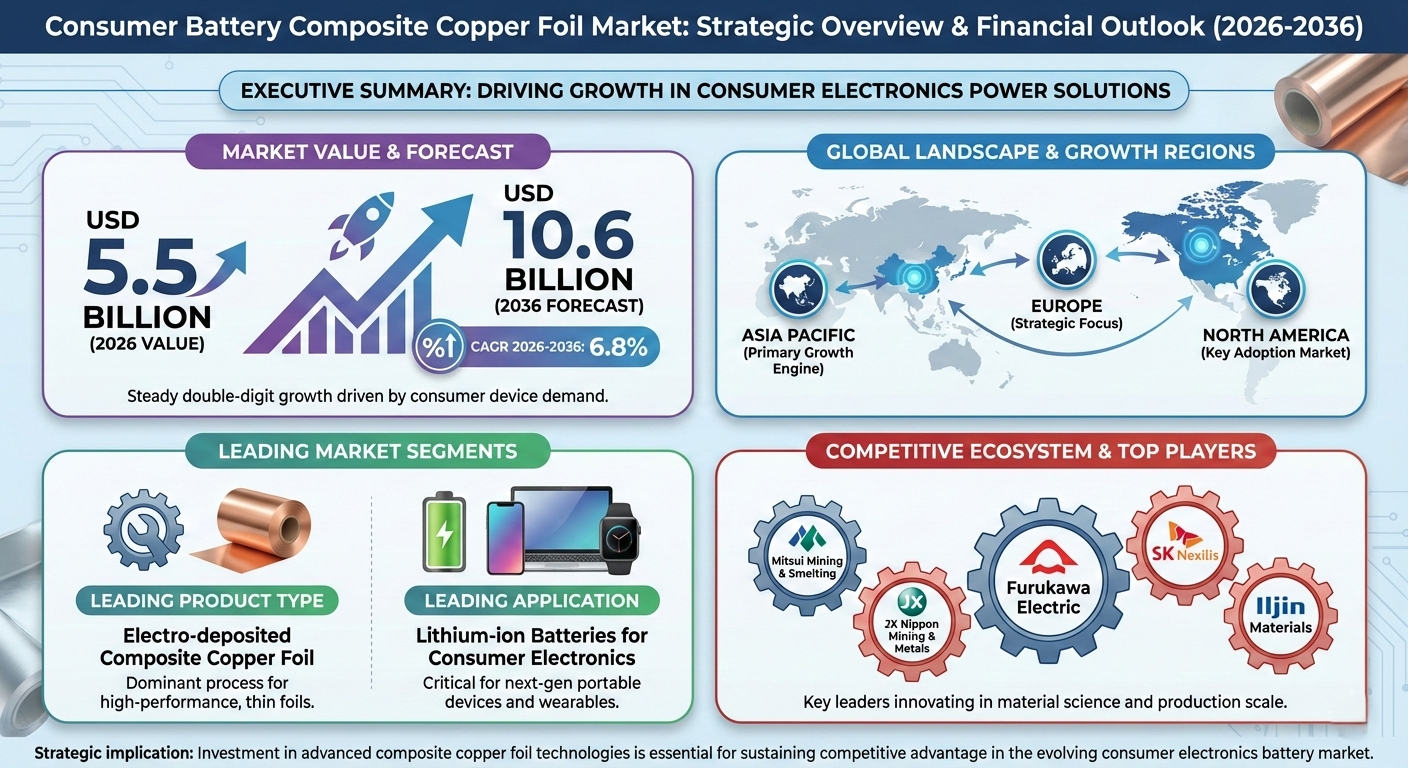

Global Consumer Battery Composite Copper Foil Market to Reach USD 10.6B by 2036; Forecast CAGR 6.8%

Market growth driven by consumer electronics battery demand, qualification cycles, supply chain dynamics, and regional expansion across Asia Pacific & the West.

NEWARK, DE, UNITED STATES, January 30, 2026 /EINPresswire.com/ -- The global Consumer Battery Composite Copper Foil Market is projected to grow significantly over the coming decade as demand intensifies for advanced current collectors in lithium-ion batteries for consumer electronics, according to a new industry analysis. The market’s expansion is shaped by strict material qualification standards, evolving battery design priorities, and a shift toward lightweight, high-performance materials that support longer cycle life and efficient manufacturing.

Market Growth Overview: Who, What, When, Where, Why, and How

Who: Leading suppliers in the consumer composite copper foil space include established materials producers such as Furukawa Electric, Mitsui Mining & Smelting, JX Nippon Mining & Metals, SK Nexilis, and Iljin Materials — firms that have secured positions through quality control, process stability, and long-term qualification with major battery OEMs.

What: The Consumer Battery Composite Copper Foil Market encompasses advanced composite foils used as current collectors in lithium-ion cells for consumer electronics such as smartphones, laptops, wearables, power tools, and other portable devices. Composite copper foil pairs a thin conductive copper layer with reinforcing substrates to reduce weight and enhance performance compared to traditional rolled copper.

When: Market forecasts extend through 2036, with growth following long battery platform life cycles rather than quarterly device shipment swings. Qualification and validation stages typically lock in material specifications early in cell platform development, anchoring demand over multi-year product cycles.

Where: Major regional contributors to market growth include Asia Pacific, Europe, and North America. Asia Pacific leads in manufacturing capacity and consumption, driven by high concentration of electronics assembly and battery production facilities.

Why: Structural material improvements supporting higher energy density and thinner current collectors are central to the market’s growth. Battery engineers increasingly choose composite foil for its balance of electrical performance, weight reduction, and production yield stability.

How: Manufacturers and procurement teams emphasize approved supplier relationships, robust quality validation, and yield management practices, integrating foil selection into broader cell design and production protocols.

Market Dynamics: Demand Drivers and Qualification Discipline

Market growth is anchored in the rising requirement for higher energy density and improved manufacturing efficiency in lithium-ion cells for consumer electronics. Composite copper foils have become integral to current collector design because they enable thinner electrodes and support tighter thickness tolerances that enhance both capacity and cycle performance.

Qualification cycles are a pivotal stage in demand generation. Once a composite copper foil grade is validated for a specific cell platform, procurement decisions and production line integration tend to remain fixed for extended periods. This “qualification lock-in” reduces supplier switching and increases volume stability for approved materials.

Procurement behavior is shaped by quality metrics such as surface treatment uniformity, peel strength, and defect control. Purchasing teams often defer heavy price negotiations until after successful throughput validation, emphasizing long-term performance and yield stability over short-term cost savings.

Product Segmentation and Application Insights

Composite copper foil products are segmented by processing method and performance characteristics:

• Electro-deposited composite copper foil: Favored for high-volume production due to tight thickness control and consistent surface morphology.

• Rolled composite copper foil: Offers enhanced mechanical properties and edge stability but at higher processing cost.

• High-strength and ultra-thin variants: Targeted at specific cell formats requiring extreme performance metrics or space constraints.

In terms of application, lithium-ion batteries for mainstream consumer electronics represent the largest share of demand, thanks to standardized cell formats and high production volumes. Smaller devices like wearables and portable accessories also contribute, particularly where ultra-thin foil performance is critical.

Regional Outlook and Competitive Landscape

Asia Pacific remains the dominant region, supported by strong electronics manufacturing ecosystems and large battery assembly operations. Regional suppliers benefit from proximity to major OEMs and integrated supply structures.

In North America and Europe, demand growth is supported by stable consumption patterns in consumer devices and complementary industrial policies aimed at bolstering local materials supply chains.

The competitive environment rewards suppliers with proven quality, long-term delivery reliability, and deep engagement in cell design validation processes. Once integrated into approved material lists, suppliers enjoy multi-year volume commitments tied to platform production runs.

Industry Relevance and Strategic Outlook

The evolution of consumer battery composite copper foil reflects a broader industry shift toward materials that optimize battery performance and manufacturing yield in high-volume cell production environments. Current collectors, historically considered commodity items, now play a more strategic role in battery performance and cost structures.

As battery designs continue to evolve toward lighter, higher-capacity cells with increased energy demands, the role of composite copper foil is expected to strengthen. Integration of advanced materials and tighter manufacturing tolerances will likely continue to shape supplier competition and selection criteria.

Request for Sample Report | Customize Report |purchase Full Report – https://www.futuremarketinsights.com/reports/sample/rep-gb-31354

Explore More Related Studies Published by FMI Research:

Ferrite Market https://www.futuremarketinsights.com/reports/ferrite-market

High-Performance Fibers for Defense Market https://www.futuremarketinsights.com/reports/high-performance-fibers-for-defense-market

USA and Canada Potassium Sulfate Market https://www.futuremarketinsights.com/reports/usa-and-canada-potassium-sulfate-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

rahul.singh@futuremarketinsights.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.