Independent UV-C Results for Room Air & Non-Porous Surfaces (Controlled Testing)

For facility operations and environmental services teams evaluating supplemental UV-C devices for environmental microbial reduction

Why C. difficile Matters as a Benchmark: Across the studies below, C. difficile results are highlighted to provide a stringent point of reference.”

CHESTER, CT, UNITED STATES, October 15, 2025 /EINPresswire.com/ -- Executive Summary (Controlled Testing Results)— John Flynn, Integrated UVC Solutions

Hard, non-porous surfaces (controlled testing): At 5 ft for 10 min, Candida auris was reduced by >3.62 log₁₀ (>99.98%); at 5 ft for 5 min, Clostridioides difficile spores showed a 3.83 log₁₀ (99.985%) reduction.¹

Air (controlled aerosol-chamber testing, 15 min): >6.34 log₁₀ for MS2 bacteriophage (viral surrogate), >5.26 log₁₀ for Staphylococcus aureus, >4.73 log₁₀ for Escherichia coli, and 4.77 log₁₀ (99.998%) for Cladosporium cladosporioides (a mold commonly isolated from indoor air).² ³

Dose mapping and room positions (peer-reviewed): In controlled exposures, C. difficile achieved >2–3 log₁₀ at 4 ft/5 min and 2–4 log₁₀ at 10 ft/15 min (direct line of sight). MRSA and VRE achieved >4 log₁₀ reductions under direct exposure.⁴

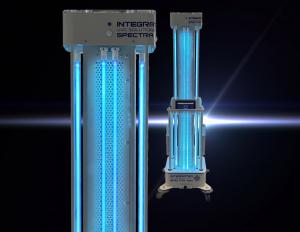

Engineering: The Spectra 1000’s patented design (U.S. Patent No. 8,791,441) integrates high-output UV-C lamps with airflow to help maintain lamp operating temperature and consistent UV-C delivery; it operates from a standard wall outlet.¹ ² ³ ⁴

Why C. difficile Matters as a Benchmark

Spore-forming organisms like C. difficile are more difficult to inactivate than vegetative bacteria and many yeasts, making them a conservative benchmark for UV-C performance on hard, non-porous surfaces. Across studies below, C. difficile results are highlighted to provide a stringent point of reference.¹ ² ³ ⁴

Selected controlled-condition results

Organism: Candida auris | Matrix: Hard, non-porous surface | Exposure: 5 ft, 10 min | Result: >3.62 log₁₀ (>99.98%) | Notes & Source: Independent lab, controlled carriers. Microchem 2024 ¹

Organism: C. difficile spores | Matrix: Hard, non-porous surface | Exposure: 5 ft, 5 min | Result: 3.83 log₁₀ (99.985%) | Notes & Source: Independent lab, controlled carriers. Microchem 2014 ¹ ² ³

Organism: MS2 bacteriophage (viral surrogate) | Matrix: Air (aerosol chamber) | Exposure: 15 min | Result: >6.34 log₁₀ | Notes & Source: Independent lab, controlled chamber. Microchem 2015 ²

Organism: Staphylococcus aureus | Matrix: Air (aerosol chamber) | Exposure: 15 min | Result: >5.26 log₁₀ | Notes & Source: Independent lab, controlled chamber. Microchem 2015 ²

Organism: Escherichia coli | Matrix: Air (aerosol chamber) | Exposure: 15 min | Result: >4.73 log₁₀ | Notes & Source: Independent lab, controlled chamber. Microchem 2015 ²

Organism: Cladosporium cladosporioides | Matrix: Air (aerosol chamber) | Exposure: 15 min | Result: 4.77 log₁₀ (99.998%) | Notes & Source: Independent lab, controlled chamber. Microchem 2015 ³

Organism: C. difficile spores | Matrix: Room dose mapping (direct) | Exposure: 4 ft, 5 min | Result: >2–3 log₁₀ | Notes & Source: Peer-reviewed, room-positioned dosimetry. Boyce et al., 2016 ⁴

Organism: C. difficile spores | Matrix: Room dose mapping (direct) | Exposure: 10 ft, 15 min | Result: 2–4 log₁₀ | Notes & Source: Peer-reviewed, room-positioned dosimetry. Boyce et al., 2016 ⁴

Organisms: MRSA & VRE | Matrix: Room dose mapping (direct) | Exposure: Per protocol | Result: >4 log₁₀ | Notes & Source: Peer-reviewed, direct exposure. Boyce et al., 2016 ⁴

All results reflect reductions under controlled conditions and are not intended to predict outcomes in occupied spaces or clinical use.

Implementation.

Notes for Facilities

Adjunct to manual cleaning: Use UV-C only after thorough manual cleaning per facility protocols; UV-C does not remove soils and serves as a supplemental microbial-reduction step.

Line of sight matters: UV-C is most effective in direct line of sight; consider room geometry, shadowing, and placement (dose-mapping data provide planning guidance).⁴

Exposure planning: Match time and distance to target organisms and turnover goals (e.g., 5–15 min cycles shown in studies).¹ ² ³ ⁴

Air vs. hard surfaces: Controlled aerosol-chamber results demonstrate airborne indicator reductions; surface testing with C. difficile and C. auris provides a conservative surface benchmark.¹ ² ³

Training & safety: Follow device labeling for safe operation (avoid skin or eye exposure). Use signage and controls per facility policy.

About the Technology

Spectra 1000 UV-C system — U.S. Patent No. 8,791,441 High-output UV-C lamps and engineered airflow help maintain optimal lamp temperature for consistent UV-C output. Operates from a standard wall outlet. Full study details and supporting documentation are available at www.iuvcs.com¹ ² ³ ⁴

Regulatory & Compliance Notes (FIFRA Pesticidal Device)

This communication summarizes independent laboratory and peer-reviewed results obtained under controlled conditions and is intended for professional audiences. Use only as directed on device labeling.

Devices are produced in an EPA-registered establishment (EPA Est. No. [98867-CT-1) and are subject to FIFRA device labeling requirements (40 CFR § 156.10).

EPA does not review or approve pesticidal devices for safety or efficacy. Statements herein describe laboratory reductions of test microorganisms and are not claims to treat, cure, or prevent disease in humans or animals.

Sources for all studies

1. Microchem Laboratories — Candida auris Controlled Surface Study (2024).

2. Microchem Laboratories — C. difficile Controlled Surface Study (2014); MS2 Bacteriophage, Staphylococcus aureus, Escherichia coli (Controlled Aerosol-Chamber Testing, 2015).

3. Microchem Laboratories — Cladosporium cladosporioides (Controlled Aerosol-Chamber Testing, 2015).

4. Boyce J.M. et al. (2016). Infection Control & Hospital Epidemiology — Measurements of UV-C dose and microbial reduction across room positions using the Spectra 1000.

Patented design reference: U.S. Patent No. 8,791,441. Full study details: www.iuvcs.com.

Sarah Crisp

Integrated UVC Solutions

email us here

Visit us on social media:

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.